Polyaspartic and polyurea floor coatings are popular choices for enhancing the durability and aesthetics of concrete floors. These coatings are known for their quick curing times and robust protective qualities. Understanding the differences and similarities between these two options can help you make an informed decision for your flooring needs.

Definition of Polyurea

Polyurea is a type of elastomer derived from the reaction of an isocyanate component and a resin blend component. It is known for its rapid curing time and exceptional resistance to abrasion and chemicals. Polyurea coatings are often used in industrial settings due to their durability and flexibility.

Definition of Polyaspartic

Polyaspartic is a type of polyurea that has been modified to allow for a longer working time. This makes it easier to apply, especially in larger areas. Polyaspartic coatings offer similar benefits to polyurea, such as chemical resistance and durability, but with added UV stability, making them suitable for outdoor applications.

Benefits of Polyaspartic and Polyurea Coatings

Both polyaspartic and polyurea coatings provide excellent protection against wear and tear, chemical spills, and UV damage. They are also known for their quick curing times, which means less downtime for your flooring project. Additionally, these coatings offer a high-gloss finish that enhances the appearance of any space.

- Rapid curing time

- High resistance to chemicals and abrasion

- UV stability (especially for polyaspartic)

- High-gloss finish

Why Compare Polyaspartic and Polyurea Coatings

Understanding Project Requirements

Choosing the right floor coating depends on the specific requirements of your project. Factors such as the environment, expected foot traffic, and exposure to chemicals or UV light should be considered. Understanding these needs will help you select the most suitable coating.

Choosing the Right Coating for Your Space

The choice between polyaspartic and polyurea coatings often comes down to the specific needs of your space. Polyaspartic coatings are ideal for areas exposed to sunlight, while polyurea is better suited for industrial environments due to its rapid curing and flexibility.

Importance of Long-Term Performance

Long-term performance is crucial when selecting a floor coating. Both polyaspartic and polyurea offer excellent durability, but their performance can vary based on environmental conditions and maintenance practices. Evaluating the long-term benefits can ensure you get the best value for your investment.

- Consider environmental factors

- Evaluate expected foot traffic

- Assess exposure to chemicals and UV light

Key Differences Between Polyaspartic and Polyurea

UV Damage Protection

Polyaspartic coatings offer superior UV protection compared to polyurea, making them ideal for outdoor applications. This UV stability helps prevent yellowing and degradation over time, ensuring the coating maintains its appearance and performance.

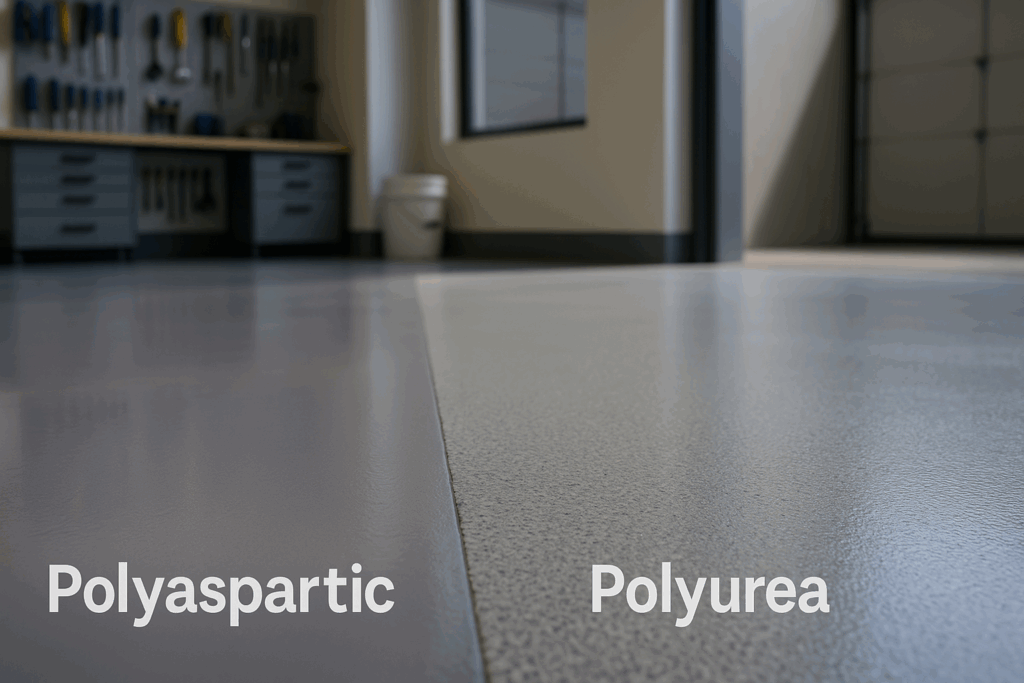

Surface Protection and Durability

Both coatings provide excellent surface protection, but polyurea is known for its exceptional durability in industrial settings. Its flexibility allows it to withstand heavy impacts and abrasion, making it a preferred choice for high-traffic areas.

Workability and Curing Time

Polyaspartic coatings have a longer working time, making them easier to apply over large areas. In contrast, polyurea cures rapidly, which can be advantageous in time-sensitive projects but may require more skilled application.

Bonding Performance

Polyurea coatings are known for their strong bonding capabilities, which ensure a long-lasting finish. Polyaspartic also offers good adhesion but with the added benefit of UV stability, making it suitable for a wider range of applications.

Cost Considerations

Polyaspartic coatings tend to be more expensive than polyurea due to their enhanced UV protection and longer working time. However, the cost difference can be justified by the specific needs of your project and the long-term benefits offered by each coating.

| Feature | Polyaspartic | Polyurea |

| UV Protection | Excellent | Moderate |

| Durability | High | Very High |

| Curing Time | Moderate | Fast |

| Bonding Performance | Good | Excellent |

| Cost | Higher | Lower |

Similarities of Polyaspartic and Polyurea Coatings

High Aesthetic Appeal

Both polyaspartic and polyurea coatings offer a high-gloss finish that enhances the visual appeal of any space. This aesthetic quality makes them popular choices for both residential and commercial applications.

Design Versatility

These coatings are available in a variety of colors and finishes, allowing for customization to suit any design preference. This versatility makes them suitable for a wide range of applications, from garages to retail spaces.

Quick Project Turnaround Time

The rapid curing times of both coatings mean that projects can be completed quickly, minimizing downtime. This is particularly beneficial for commercial spaces that cannot afford extended closures.

Application Process

The application process for both coatings is similar, involving surface preparation, mixing, and application. However, the specific techniques may vary based on the product and environmental conditions.

Low Maintenance

Once applied, both polyaspartic and polyurea coatings require minimal maintenance. Regular cleaning and occasional resealing can help maintain their appearance and performance over time.

- High-gloss finish

- Variety of colors and finishes

- Rapid curing times

- Similar application process

- Minimal maintenance required

Durability and Strength of Polyaspartic vs. Polyurea

Lifespan and Maintenance

Both polyaspartic and polyurea coatings offer long-term performance with proper maintenance. Regular cleaning and occasional resealing can extend their lifespan, ensuring they continue to protect and enhance your floors for years.

Temperature and Weather Resistance

Polyurea coatings are known for their flexibility, allowing them to perform well in extreme temperatures. Polyaspartic coatings, with their UV stability, are better suited for areas with high sun exposure. Both coatings can be applied year-round, provided the environmental conditions are suitable.

- Long-term performance with maintenance

- Suitable for extreme temperatures

- Year-round application potential

Application and Curing Time

Workability of Polyaspartic and Polyurea

Polyaspartic coatings offer a longer working time, making them easier to apply over large areas. This workability is beneficial for detailed projects or when working in challenging conditions. Polyurea, with its rapid curing time, is ideal for projects requiring quick turnaround.

Floor Preparation Process

Proper floor preparation is crucial for optimal results with both coatings. This includes cleaning, repairing any damage, and ensuring the surface is dry and free of contaminants. Following these steps ensures strong adhesion and a long-lasting finish.

- Longer working time for polyaspartic

- Rapid curing for polyurea

- Essential floor preparation steps

Cost Considerations for Polyaspartic and Polyurea Coatings

Budgeting for Floor Coatings

When budgeting for floor coatings, consider the initial cost, long-term benefits, and maintenance requirements. Polyaspartic coatings may have a higher upfront cost, but their UV stability and longer working time can offer better value for certain projects.

- Initial cost vs. long-term benefits

- Maintenance requirements

- Value for money

Downsides of Polyaspartic and Polyurea Coatings

Limitations and Challenges

While both coatings offer numerous benefits, they also have limitations. Polyaspartic coatings can be more expensive, and polyurea requires skilled application due to its rapid curing time. Consider these factors before deciding on the best coating for your project.

- Higher cost for polyaspartic

- Skilled application needed for polyurea

- Considerations for specific project needs

Finding the Best Concrete Flooring Coating for You

Evaluating Your Needs

To find the best concrete flooring coating, evaluate your specific needs, including environmental conditions, expected foot traffic, and aesthetic preferences. Custom solutions, such as those offered by Duramen Bay Area, can help you achieve the desired results for your space.

- Assess environmental conditions

- Consider foot traffic and aesthetics

- Explore custom solutions with Duramen Bay Area

For tailored flooring recommendations, commercial or residential projects in the Bay Area, consult a certified Duraamen installer for the right coating system.

Conclusion

Polyaspartic and polyurea coatings each offer durable, attractive, and fast-curing solutions for concrete floors. Polyurea stands out in industrial environments where flexibility and rapid installation matter most, while polyaspartic coatings excel in UV-exposed or decorative spaces thanks to their superior sunlight resistance and longer application window. For Bay Area properties, where garage spaces, patios, and commercial floors face both moisture and sun exposure, polyaspartic often provides the best balance of durability and long-term appearance. Choosing a certified installer ensures proper surface prep, strong adhesion, and a finish built to last.

People Also Asked

What are the advantages of using polyaspartic over polyurea?

Polyaspartic coatings offer superior UV resistance and a longer working time compared to polyurea. This makes them ideal for outdoor applications and projects requiring more detailed work. Additionally, their enhanced UV stability helps maintain the coating’s appearance over time.

Can polyaspartic and polyurea coatings be used together?

Yes, polyaspartic and polyurea coatings can be used together to leverage the benefits of both materials. Combining them can provide enhanced UV protection and rapid curing times, making them suitable for a variety of applications. This compatibility allows for tailored solutions to meet specific project needs.

How do polyaspartic and polyurea coatings perform in different climates?

Both coatings perform well in a range of climates, but polyaspartic offers better UV stability, making it more suitable for sunny environments. Polyurea’s flexibility allows it to withstand temperature fluctuations, making it ideal for areas with extreme weather conditions. Their performance can be optimized with proper application and maintenance.

How long do polyaspartic and polyurea coatings last?

Polyaspartic and polyurea coatings can last for many years with proper maintenance. Their longevity depends on factors such as environmental conditions, foot traffic, and regular cleaning. Both coatings offer durable protection, making them a worthwhile investment for your flooring needs.

Can these coatings be applied to vertical surfaces?

Yes, both polyaspartic and polyurea coatings can be applied to vertical surfaces, offering versatility in application. This makes them suitable for a variety of projects, including walls and other non-horizontal surfaces. Proper application techniques ensure strong adhesion and a smooth finish.

Are polyaspartic and polyurea coatings DIY-friendly?

While it is possible to apply these coatings as a DIY project, professional application is recommended for the best results. Professionals have the expertise and equipment to ensure proper surface preparation and application, leading to a long-lasting and high-quality finish.